Catch-22

-

Posts

1,772 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Posts posted by Catch-22

-

-

-

-

-

RS80 is an excellent powder. I use it in my .338 Norma Mag with 300gn Scenars. Superb ES/SD with good velocity. Perfect in .338LM and heavy bullets.

-

Bump, still for sale!

-

RAMSHOT Magnum and Vhit 340 still here!

-

Proof still for sale!

-

It is a bargain. The BA Comp chassis has been the top chassis system used in the top flight PRS league for the last 5yrs running.

I love mine.

Good luck with the sale.

-

I think this looks brilliant - a lot of amalgamation of the top features all in one action.

My only doubt is the optimisation for AW mags. Most chassis systems and bottom metal units on the market support AICS pattern mags. Few support AW mags.

It seems the action will work with AICS but with a number of caveats, including some additional fudging of AICS mags to get the bolt to ride properly.

To me, the above could be its weakness. Hopefully not. Time will tell.

-

59 minutes ago, ruger7717 said:

Good doing business with you😉

nice easy transaction!

Likewise - thanks again…enjoy the Bartlein!

-

2 hours ago, levelplaying said:

Is the proof research stainless part number 113738

https://proofresearch.com/barrels/bolt-action/

Thanks

Hiya,

Yes that’s right…it’s the Competition contour with 1-8” twist.

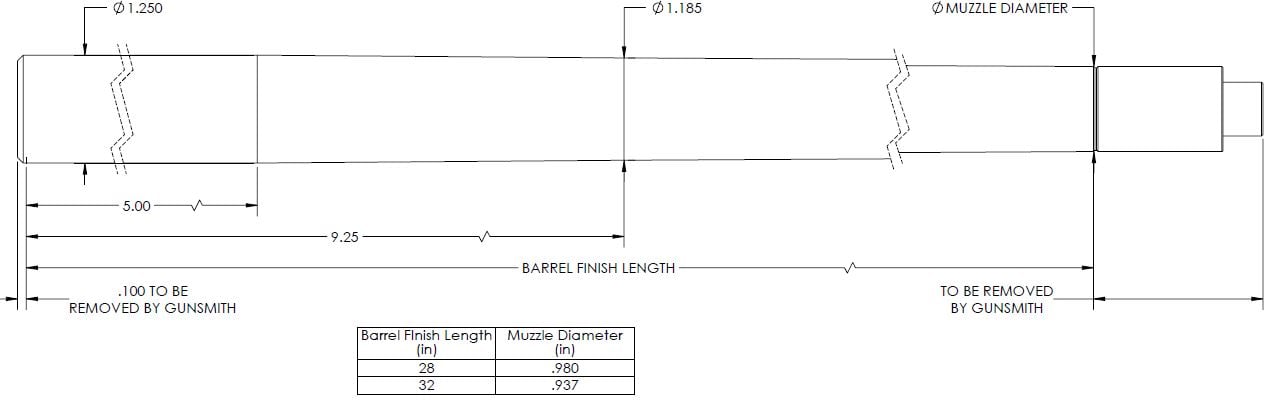

It is a beast, 1.25” at the shank, straight profile for 5” and very gentle taper.

The sister barrel currently on my Impact 737r is finished at 26” long and it’s awesome. It’s probably the fattest barrel contour you can get before a 1.25” straight.

-

Bartlein barrel now SOLD!

Proof Research barrel still here 👍

-

PMC, and Wolf, are the same as Murom…same factory.

-

On 12/16/2022 at 9:39 AM, chrisnic365 said:

Does anyone know of a UK supplier of scope covers like this:

https://www.impactproshop.net/product/scope-saver/

Given some of the stages I watched I'd like to have one before I try out some PRS.

thanks

Why do you need an expensive cover…which is likely to start flopping about and get in the way anyway? The example cover you show also only covers the Objective end anyway. What about the rest of the scope - that’s also equally bound to be scratched too?!

Use some simple ‘snipers’ fabric adhesive. Same stuff as medical sticky wrap. I got a roll off eBay for about £3 which will outlast my lifetime.

I use it on all my PMIIs and it’s great. Been out in the rain and shine for the last few years and never lost its stick. Stays nice and tight on the scope…won’t fall off!

-

New Years Eve bump.

Can bring powder to MOD shoots or leave at the MDRC tunnel with your name on. Or collect in person from my gaff.

-

Two barrel blanks (Unchambered).

#1 Bartlein, Stainless, 1-8” twist, 5r rifling, 6.5mm, 27” long, HEAVY Varmint contour. SOLD!

#2 Proof Research, Stainless, 1-8” twist, 5r rifling, 6.5mm, 28” long, Proofs Competition contour (heavier than Heavy Varmint). SOLD!

NB: ignore the ‘thin’ bit on the end of the proof muzzle…that all gets chopped off when the barrel is chambered and crowned.

I have sisters of both these barrels on my rifles currently. A 26” finished Bartlein on a Defiance in 6.5x47 and a 26” Proof on my MPA Impact, also in 6.5x47.

Both the sister barrels shoot very well in deed. I took my Impact with Proof barrel to the tunnel this morning and each 5 shot group was consistently in the 0.2s or better.

Prices include postage to U.K. mainland.

I don’t have any ‘poster’ tubes for shipping, so please bear with me if you want a barrel quickly.

Cheers

-

I always found 155gn Scenars and N140 to be a good solid combination in .308w.

-

Bear in mind coated bullets use a higher charge to get the bullet to the same speeds as uncoated bullets because the coating reduces friction and pressure build up.

I found this using HbN for both 6.5 and .338. Typically I had to up my charges by around 1.5gn to 2.0gn above uncoated bullets in 6.5x47 with 123gn bullets.

In my .338 Norma Magnum, 300gn bullet, my charges are about 3.0gn higher than uncoated bullets.

So if you’re using load data for coated bullets, I would reduce the charge by at least 1.5gn if using uncoated bullets.

stay safe 👍

-

All sold.

Many thanks all - Merry Christmas 🎅🎄🎁

-

I prefer to clean my cases because;

1. it stops transfer of all the carbon and other toxic chemicals on your hands when handling

2. stops transfer of soot/carbon from case necks into the neck and chamber area. My thought is this should help to reduce things like carbon ring build up - though I do still try and clean the neck/throat/chamber areas after each shoot

3. reduces likelihood of dirty primer pockets causing ignition issues through the flash hole

If the goal of Precision reloading is to make every round the same in every way, every time it’s reloaded, then I think cleaning is one of those steps, otherwise you get carbon build up in different ways.

I also anneal, but will use a lube inside the necks (graphite or HbN) before seating to ensure a consistent bullet release. Annealed cases are rather ‘grippy’ on bullets.

-

4 hours ago, Ralpharama said:

Go on, you twisted my arm 🤣 - I’ll take you up on the case trimmer 😃

PM inbound 😋

-

UPDATE

Butler Creek lans caps - SOLD

Tier One scope leveller - SOLD

Redding stuck case removal - SOLD

EXD reticle alignment tool - SOLD

Redding case trimmer - SOLD

-

31 minutes ago, Dellboy said:

stuck case removal kit please pm me payment details

PM sent.

-

1 hour ago, Roy W said:

I'll take the Butler Creeks please

PM replied to.

SKB iSeries 6018-8 waterproof case

in For Sale (Free Adverts for Private Secondhand Items only)

Posted

Further Reduced to £275