levelplaying

-

Posts

199 -

Joined

Content Type

Profiles

Forums

Events

Articles

Posts posted by levelplaying

-

-

Is this FFP and Is there a transferrable warranty on this. Thanks

-

-

For sale, as in title.

Never used and never mounted. In perfect condition. Still boxed with all accessories when first purchased.

https://www.opticswarehouse.co.uk/vortex-crossfire-ii-3-9x50-ir-v-brite-sfp-rifle-scope

£175 plus postage£150 plus postage -

Received. Many Thanks

-

Thanks Mattnal and Popsbengo.

I posted the question for opinions. Yes, I agree that my question may solicit responses from individuals that I have not spoken to or know, but it does open up a conversation not just for me but others that may have similar questions. Indeed, I don't know many of the people from this shooting forum as I don't know you, and naturally evaluate any advice provided carefully. However there are individuals on this forum whose opinions I do value. As you say, it's my licence and my requirements.

I agree that honesty is the best policy, and felt uncomfortable with the initial responses, but I would have employed an honest policy with my firearms officer as I have always done. I wanted some different perspectives

Regards

-

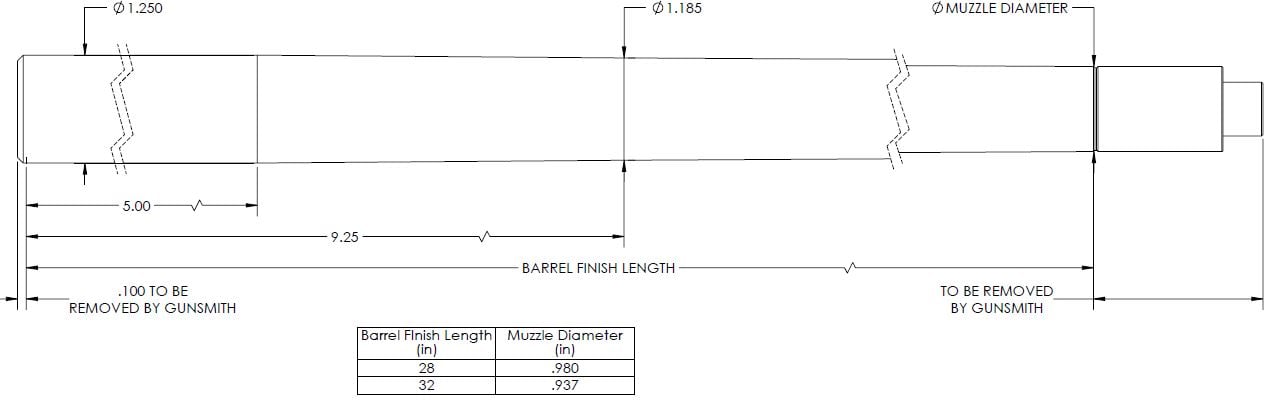

Is the proof research stainless part number 113738

https://proofresearch.com/barrels/bolt-action/

Thanks

-

I have had an FAC for some 15 years on an open basis. I have four slots, two of which are taken up, .308 and .260. The other two are for .223 and a .22 rimfire. They are currently vacant but I intend to purchase two rifles shortly so my allocation will have been used up.

If I want to purchase another .308 to be used for the same purposes as my existing .308, and another calibre, say .270 how can I justify this to the Firearms Officer on my variation request.

-

I use a nylon brush. Reluctant to use a bronze brush.

I generally run some carbon remover with a patch or two. Then copper remover (many brush strokes and patches) leaving it to soak, then carbon remover, again leaving it soak and many patches later.

However much I clean, the patch after maybe 150 strokes looks nearly as dirty as the first.!!

Barrel looks okay using a cheap Chinese bore scope, but am concerned about the very small not quite microscopic metal flakes.

-

Have for a number of years been cleaning my rifle barrels with KG1 and KG12 products using the suggested cleaning routine.

However much time I spend cleaning, I always get carbon residue on my patches. I probably run my rifle rod through the bore for both Carbon and Copper solvent no less than 150 strokes on each. It comes to the point that I loose the will and have to be content that my patches are never as clean as I would like them. How meticulous should I be. Should I persevere until there is no sign of carbon or be satisfied that there is some. I sometimes feel that I might be doing more damage than good.

In addition, I notice some very small metal particles on the patches.

Any advice or recommendations.

Thank You

-

Sorry Popsbengo. Ignore the question as to the button. Having a moment.

-

Thanks for your response.

So that I fully understand. A full Redding resize die does neck and body as long as the bush is used, as opposed to just a a neck sizing die that does just the neck.

You mention that you can just use the die to resize. Does that mean the neck doesn't get resized. Is this how other dies work, such as the Lee dies

When you say 'button' do you mean 'bush'.

I have just remeasured the the thickness of the neck and it is more or less 0.015 and see how you determine that the bushing is correct. Thank you for that bit of advice.

-

I hope someone on here can help out with my relative inexperience with Redding dies.

I was given a sizing, seating die and some once fired ammunition and ready made ammunition some years back with a rifle that I bought. The previous owner used factory GGG ammunition. The dies are .308.

I have yet to load any ammunition for this rifle and calibre. I am okay reloading for another calibre using the Lee and RCBS dies that I have, but have no experience with Redding.

I have read information on line on how to set up the die but have some concerns.

I understand that the resizing die can be used as a full length resizing die. I am not sure how the bushing comes into play. Do you use the die with the bushing to full length resize or do you remove it. Can the die be used just to resize the neck and if so how.

The bushing is stamped. 336 but measuring it with the calipers it is .335

I have measured the outer neck diameter of the factory ammo and the once fired complete ammo. These are .3365 and .3450 respectively . A difference of .0015 on the factory ammo and .0100 on the once fired ammo . This seems a large variance.

The once fired brass (before resizing) are on average .3455 which gives a difference of .0105 against the bushing.

It seems to me that having a bushing that is .105 smaller is a big variance. Will this damage the case.

If I want to do a full resize do I need to use the bushing.

Does the bushing just reduce the neck diameter . What does the bushing actually do.

Can the die be used for just resizing the neck.

Many Thanks

-

-

Thanks Richiew, that's sorted it.

Thank you all for your input and help.

Much appreciated

-

Sorry, but a little bit lost.

Have an Athlon FFP APMR MIL scope. Couldn't find this on Strelox and put another Reticle in.

I don't Understand why my scope would be set up as 1/4 moa

-

-

I thought I would ask here.

There maybe a simple explanation but I cannot quite understand this.

I have put my data in Strelok and today zeroed my rifle in on a new load.

I shot out to 100 yards and then out to 180 yards. I adjusted my scope (mil) by .6 mil and was dead centre. I didn't chronograph my ammunition, but based on an assumed speed of 2450' per second the vertical correction is 6.2 clicks which I assume to mean 0.6 Mil. However I cannot understand why the vertical MRAD correction is 0.4. Am I missing something. Does the MRAD correction not correlate to the vertical click adjustment. Could someone help out and explain why these two values are not the same.

-

Thank you all for your replies.

I have, in the main Peterson brass, and a small quantity of Remington.

In terms of primers, I have a selection of Murom, CCI and Federal.

At this present moment, I only have N150, N160, IMR4166 and H380 and wanted to know which if any of these might work with some suggested load data. I wanted to avoid purchasing a fifth powder, but if I had to then the RL19 as per the Nosler data sheet seems the best recommendation.

-

I have some Nosler Accubond LR 129 gr 6.5 .264 bullets and a choice of Vihti N150, N160, IMR4166 & H380 powder.

My Lyman reloading book does not have the 129gr bullet listed for the .260 and nor can I find any reloading data for the .260 with my current choice of powders.

Below is an extract from the Hodgdon reloading data centre:

Starting Load Maximum Loads Manufacturer Powder Bullet Diam. C.O.L Grs. Vel. (ft/s) Pressure Grs. Vel. (ft/s) Pressure Hodgdon H380 Out of Stock 0.264" 2.780" 37.8 2,572 50,800 PSI 40.7 2,738 58,900 PSI IMR IMR 4166 Out of Stock 0.264" 2.780" 33.0 2,535 50,100 PSI 35.9 2,717Bullet Weight130 GR. NOS ABCaseRemingtonPrimerRemington 9 1/2, Large Rifle59,400 PSI

I have also copied the load data below for N150 and N160 from the Vihti site

Bullet 8,4 g / 130 gr Barnes, TSX C.O.L. 70,8 mm / 2.787 inch Powder Starting load Maximum load Type Weight Velocity Weight Velocity [g] [grs] [m/s] [fps] [g] [grs] [m/s] [fps] N540 2,17 33.5 720 2362 2,44 37.7 810 2657 N550 2,26 34.9 717 2352 2,59 40.0 816 2677 N160 2,32 35.8 702 2303 2,75 42.4 808 2651 Bullet 8,5 g / 130 gr Berger, Hybrid OTM Tactical C.O.L. 71,0 mm / 2.795 inch Powder Starting load Maximum load Type Weight Velocity Weight Velocity [g] [grs] [m/s] [fps] [g] [grs] [m/s] [fps] N540 2,22 34.3 762 2500 2,51 38.7 844 2769 N150 2,17 33.5 746 2448 2,46 38.0 821 2694 N550 2,45 37.8 777 2549 2,70 41.7 855 2805 N160 2,71 41.8 786 2579 2,97 45.8 862 2828 Bullet 8,5 g / 130 gr Berger, VLD Target C.O.L. 71,0 mm / 2.795 inch Powder Starting load Maximum load Type Weight Velocity Weight Velocity [g] [grs] [m/s] [fps] [g] [grs] [m/s] [fps] N140 2,11 32.6 739 2425 2,38 36.7 814 2671 N540 2,19 33.8 761 2497 2,48 38.3 843 2766 N150 2,09 32.3 741 2431 2,42 37.3 815 2674 N550 2,46 38.0 778 2552 2,69 41.5 856 2808 N555 2,59 40.0 792 2598 2,84 43.8 864 2835 Bullet 8,5 g / 130 gr Scirocco II, Swift C.O.L. 71,0 mm / 2.795 inch Powder Starting load Maximum load Type Weight Velocity Weight Velocity [g] [grs] [m/s] [fps] [g] [grs] [m/s] [fps] N140 2,06 31.8 719 2359 2,32 35.8 785 2575 N540 2,12 32.7 734 2408 2,45 37.8 819 2687 N150 2,02 31.2 722 2369 2,34 36.1 795 2608 N550 2,30 35.5 742 2434 2,60 40.1 828 2717 N560 2,74 42.3 762 2500 3,00 46.3 846 2776

Is it safe to adopt the 130gr bullets load data and decrease the charge by a couple of gr. at either end of the scale

Any advice would be appreciated.

-

Many Thanks

-

Could anyone recommend a rifle sling for stalking. One that secures over both shoulders to stop the rifle slipping off.

Barrel is 26" plus say 5" for moderator

Many Thanks

-

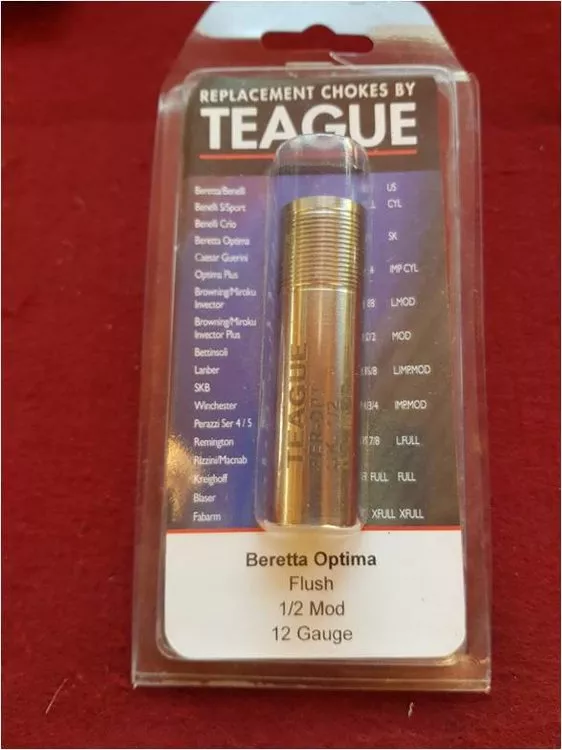

Set of Teague Beretta Optima Flush Chokes. Choked at 1/4 , 1/2 , 3/4, Full , with case and tapered key.

Cost new £210. Seling for £140 plus postage. In excellent condition. Well looked after with very little use.

***********************************************************************

Set of Teague Beretta Optima Flush Chokes. Choked at Skeet, Cylinder , 1/4, with case and tapered key.

Cost new £166. Seling for £105 plus postage. In excellent condition. Well looked after with very little use.

-

Set of Teague Beretta Optima Flush Chokes , choked at 1/4 , 1/2 , 3/4, Full , with case and tapered key.

Cost new £210. Seling for £140 plus postage. In excellent condition. Well looked after with very little use.

***********************************************************************

Set of Teague Beretta Optima Flush Chokes , choked at Skeet, Cylinder , 1/4, with case and tapered key.

Cost new £166. Seling fo £105 plus postage. In excellent condition. Well looked after with very little use.

***********************************************************************

Two Teague Beretta Optima Flush Chokes , each choked at 1/2 . Excellent condition. Selling for

£35£25 each plus postageOneTeague Beretta Optima Flush Chokes , each choked at 3/4 . Excellent condition. Selling for £25 each plus postage

-

New

in For Sale (Free Adverts for Private Secondhand Items only)

Posted

.