-

Posts

930 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Articles

Posts posted by Danpd

-

-

1 hour ago, terryh said:

Dave

Very nice and I cannot see any reason not to have a good 22rf - you have more chance/locations of using one than a CF of the same design.

Being nosey - what ‘head space’ (rim thickness) did you choose to set up for?

What ammo does it favour so far?

Can I ask what reamer design you went with? I’m looking at the Nevius

cheers T

The rifles are setup with a .043 rim thickness in mind which is CIP minimum.

Nevius design is great for match and BR application, but a poor choice for a repeating rifle if you want reliable function over the course of fire. Something along the lines of a modified Winchester 52D chamber is what most people are using.

-

10 minutes ago, brown dog said:

Holy crap. That's the pinnacle! Is that yours?

Yes indeed. A grail of mine for a while.

-

-

Having a rationalisation of reloading equipment and have the following surplus to requirements.

7 x H4831 (not SC)

9 x H1000

5 X Retumbo

2 X BLC-2

1 x H414

all are new unopened 1lb containers and priced at £45 per tub.

postage not possible.

-

Apparently Barton Gunworks import HS Precision currently

-

14 minutes ago, lee w 118 said:

Have you rebarelled in Hardy or christian arms tubes and what are your findings in perfomance and accuracy of the two againnst the proof research.

I’ve had a lot of unhappy customers with Christensen, couldn’t recommend. Have seen some shocking factory ‘bedding’ on their rifles too.

have fitted a few Hardy tubes, just average button barrels with some carbon wrapped on. Shot ok, but with the price not far from a Proof, most people would rather opt for one of those.

As I always tell my customers, the main benefit of any carbon barrel is weight saving and bling. None of them shoot better than the equivalent Bartlein etc, and generally you are double the cost of the equivalent steel blank.

-

47 minutes ago, baldie said:

Josh's is the only carbon barrel i've seen in use, that doesn't play silly buggers under sustained fire.

I shot a rifle with one of the foreign barrels fitted last weekend, and once it had got warm, extraction was "interesting"

Not something I would use or sell.

Apart from Josh's.

Their usual use, is on a hunting rifle. Hunters want light weight, and usually only fire one or two shots in a session.

Different thing entirely, on a target rifle.

Having supplied and fitted more Proof Research barrels than most in the UK, I can’t say my findings would be the same as yours.

I wish Josh all the best in his new venture, but there aren’t enough examples of his products in general use yet to give an accurate picture of their true performance.

-

Totally useless contraption. It takes longer to remove the rectum from the device than it does to gralloch the deer. I used to cull deer as part of a team and we'd take 30-40 a week, any supposed time saving devices like this were discussed and tested. this one was discarded after first session.

-

Interesting to see the process. Thank you for putting the videos together.

-

Did anyone receive and use scorpion chamber reamer by any chance ? May be looking to have a set made but seen bowers earlier but didn't think to ask doh ! atb

Bradders, MikMak and Baldie all had terrible results with them.

-

Have handled and looked through one, great scope optically, but I was disappointed with the limited 130cm total elevation adjustment.

-

As soon as I saw the Tru-Bore it made perfect sense. Rigid workholding and the ability to align barrels axially and radially. You do still need a rear spider or spindle bush to control barrel whip at high RPMs and a workaround to allow bore flushing whilst chambering, but I think it is a fantastic piece of kit for any professional gunsmith.

-

What's the load data?

That load was 59gr H1000 with a 140 Hybrid. Think the guy is running 61 now.

-

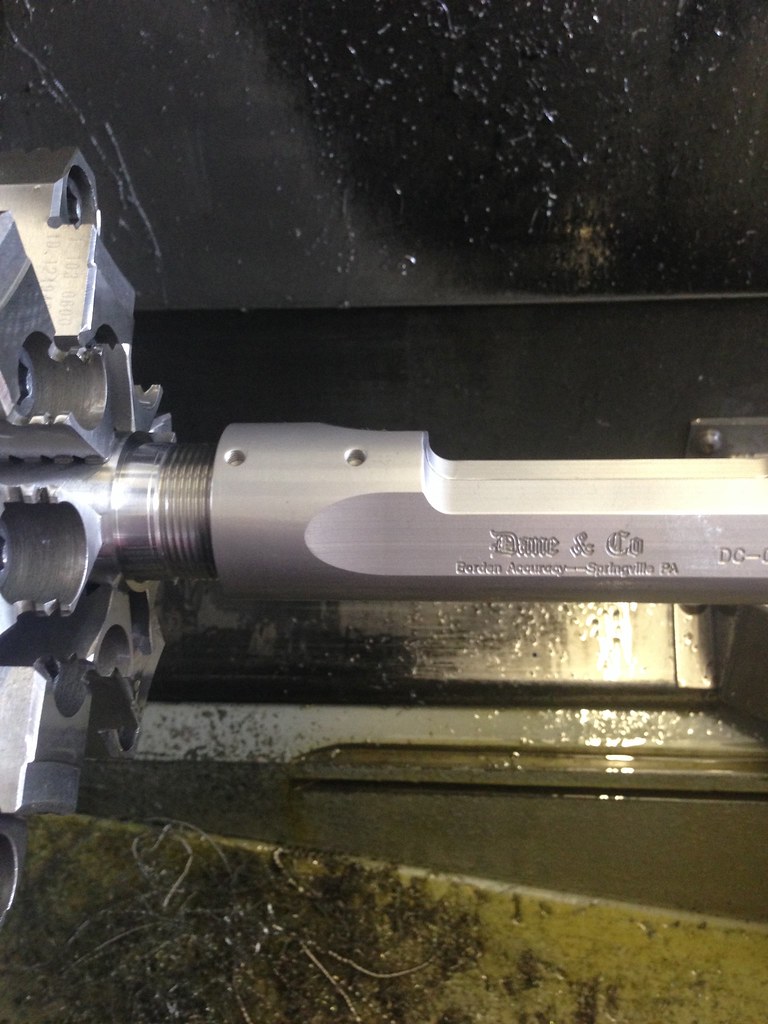

Haven't put up anything on here in a long long time, so thought i would :-)

First up are some chambering pics of a recent 6.5 SAUM Build

Krieger 8.5 Twist Blank set up in the Tru-Bore Alignment System

Untitled by Custom Rifle, on Flickr

Untitled by Custom Rifle, on FlickrTrying out the SSG dual bushing Range Rods..... no longer using these as the 2.75" Interaipd indicator is quicker and more repeatable.

Untitled by Custom Rifle, on Flickr

Untitled by Custom Rifle, on Flickr Untitled by Custom Rifle, on Flickr

Untitled by Custom Rifle, on FlickrCleaning up the face of the Blank.

Untitled by Custom Rifle, on Flickr

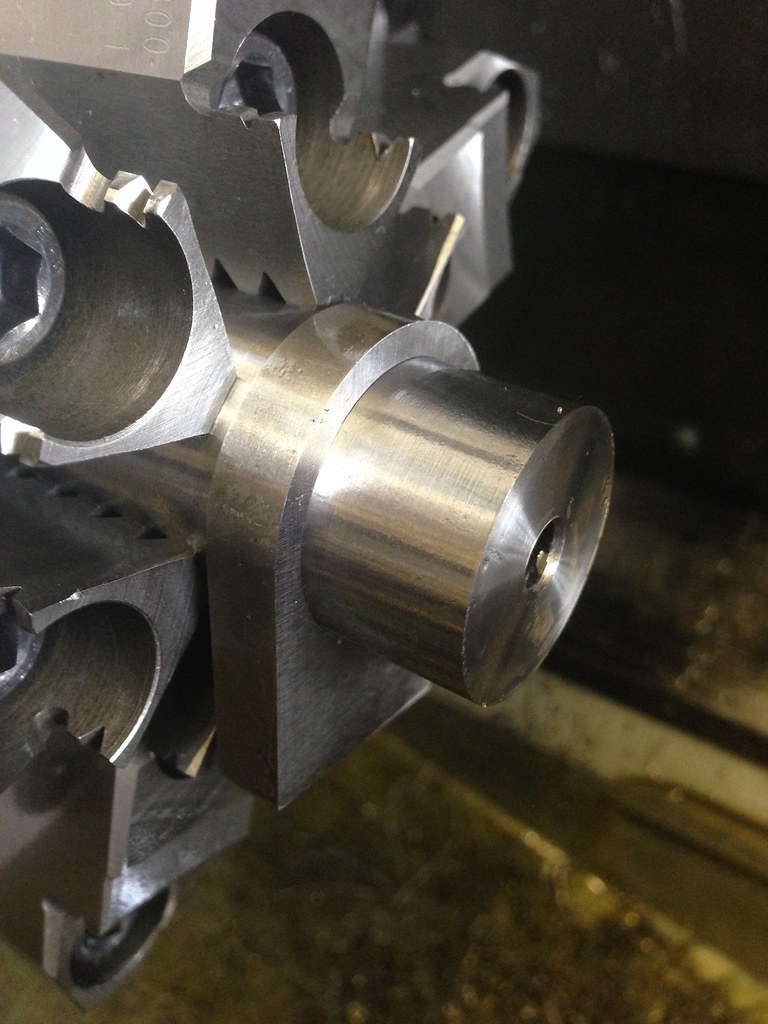

Untitled by Custom Rifle, on FlickrTenon turned for Slip fit on recoil lug

Untitled by Custom Rifle, on Flickr

Untitled by Custom Rifle, on Flickr Untitled by Custom Rifle, on Flickr

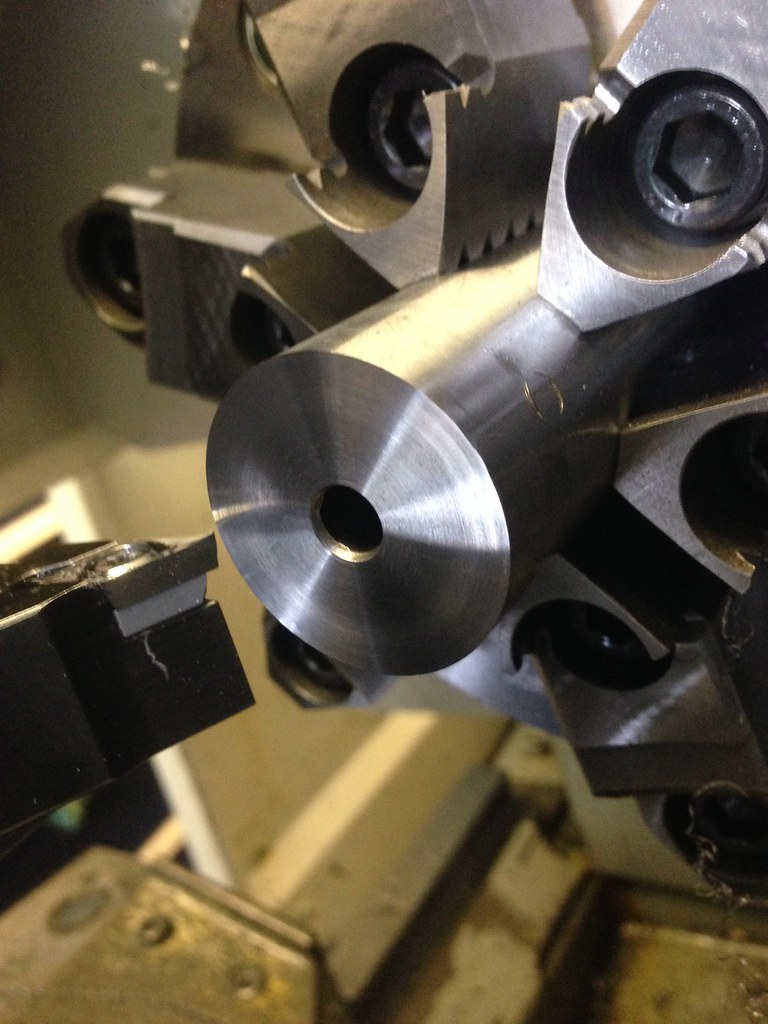

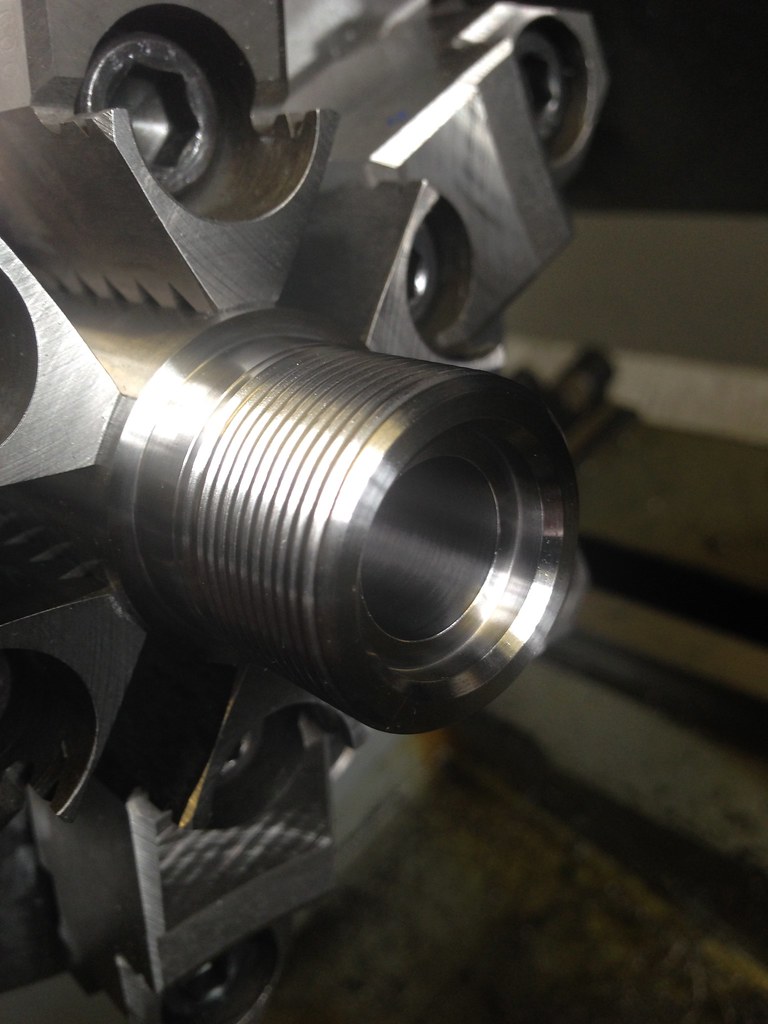

Untitled by Custom Rifle, on FlickrEstablishing Thread Major Diameter

Untitled by Custom Rifle, on Flickr

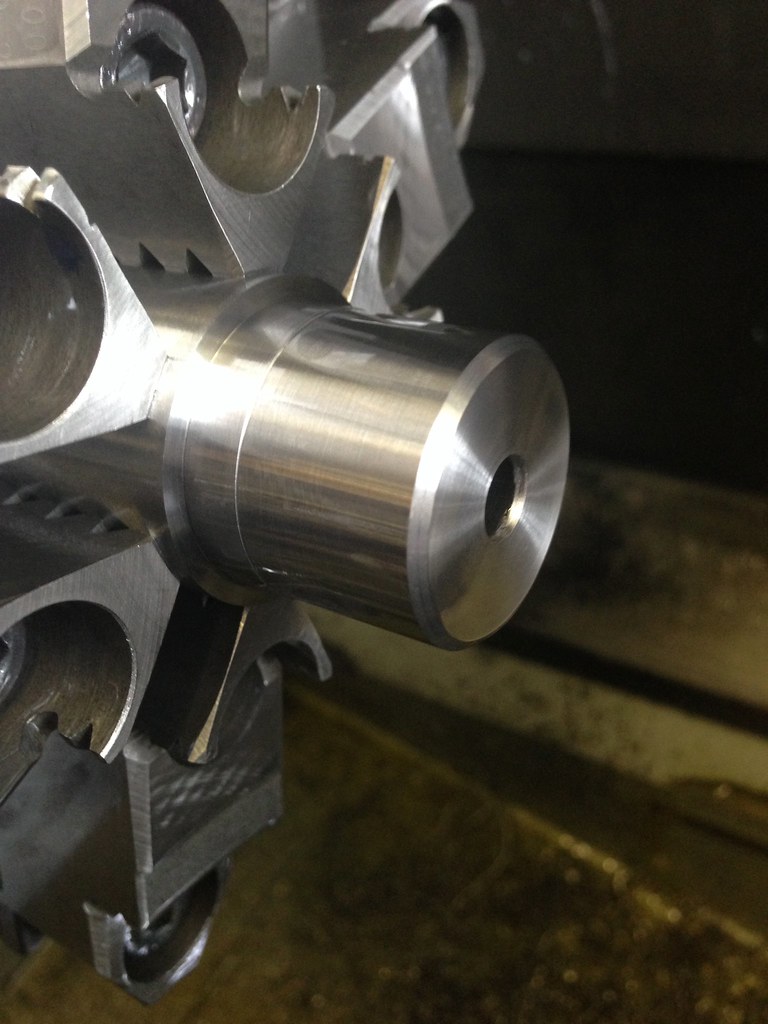

Untitled by Custom Rifle, on Flickr.040 Chamferon the end of the tenon.

Untitled by Custom Rifle, on Flickr

Untitled by Custom Rifle, on FlickrCheck the Pitch Diameter, little bit left to go.

Untitled by Custom Rifle, on Flickr

Untitled by Custom Rifle, on FlickrTest Fit Action

Untitled by Custom Rifle, on Flickr

Untitled by Custom Rifle, on Flickr Untitled by Custom Rifle, on Flickr

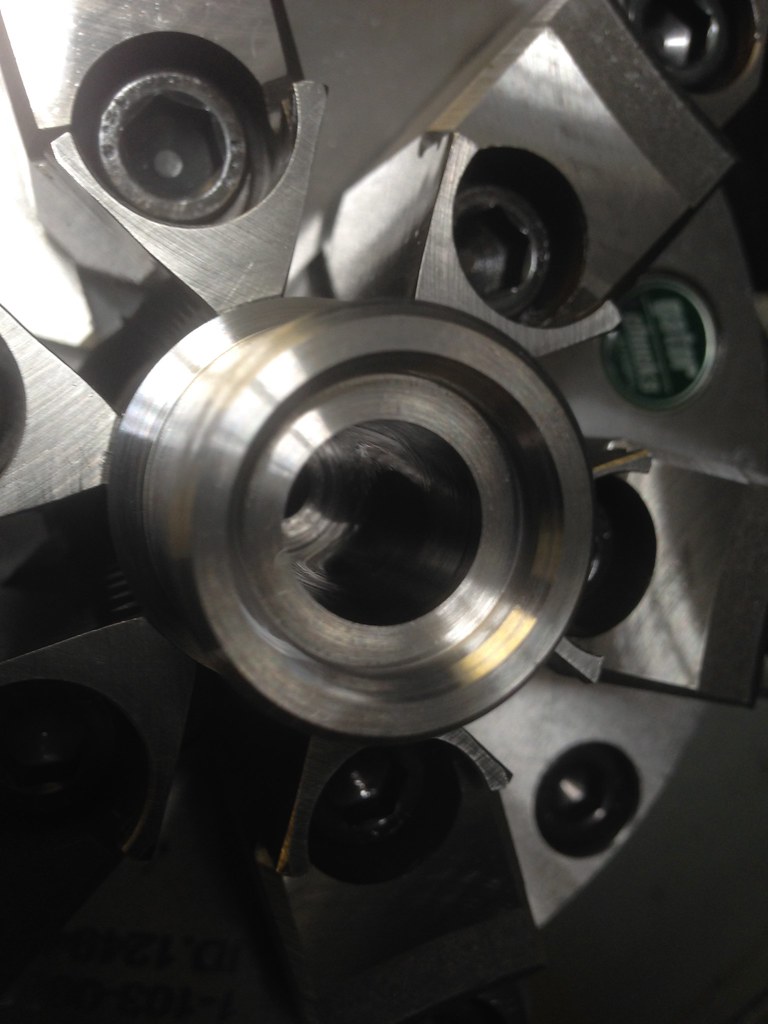

Untitled by Custom Rifle, on FlickrCut the Counterbore and ID Chamfer.

Untitled by Custom Rifle, on Flickr

Untitled by Custom Rifle, on FlickrChamber pre-bored .010 undersize and .100 short

Untitled by Custom Rifle, on Flickr

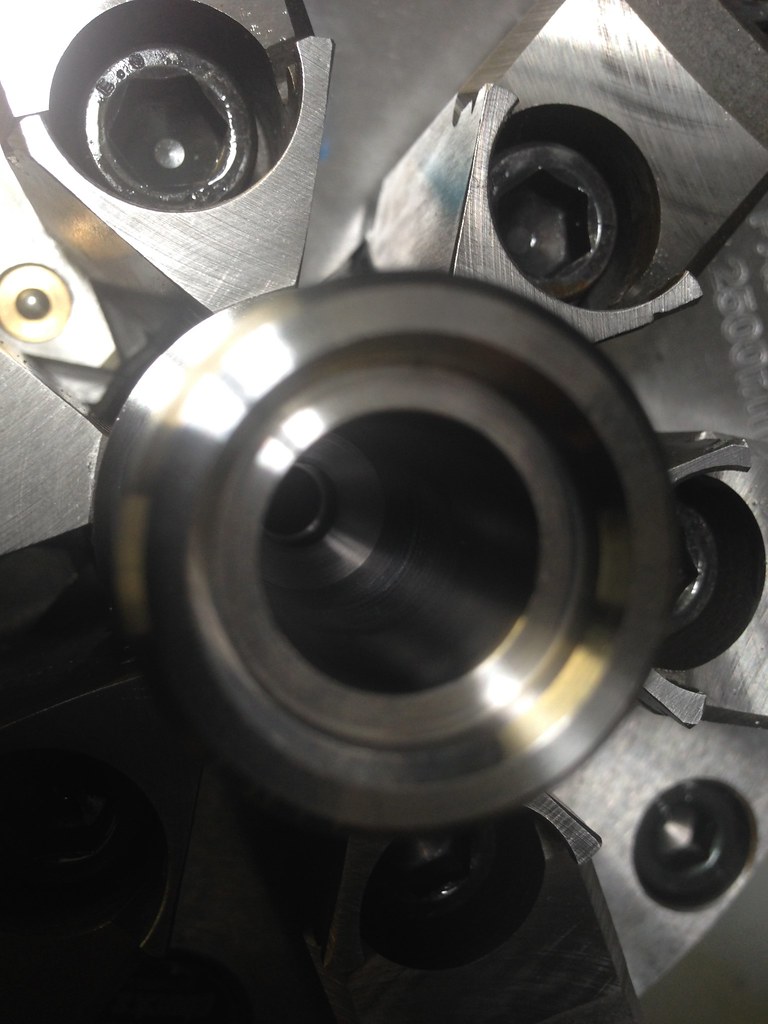

Untitled by Custom Rifle, on FlickrChecking chamber depth with in house manufactured gauging

Untitled by Custom Rifle, on Flickr

Untitled by Custom Rifle, on FlickrFinal polish, and we are there.

Untitled by Custom Rifle, on Flickr

Untitled by Custom Rifle, on Flickrby Custom Rifle, on Flickr

Untitled by Custom Rifle, on Flickr

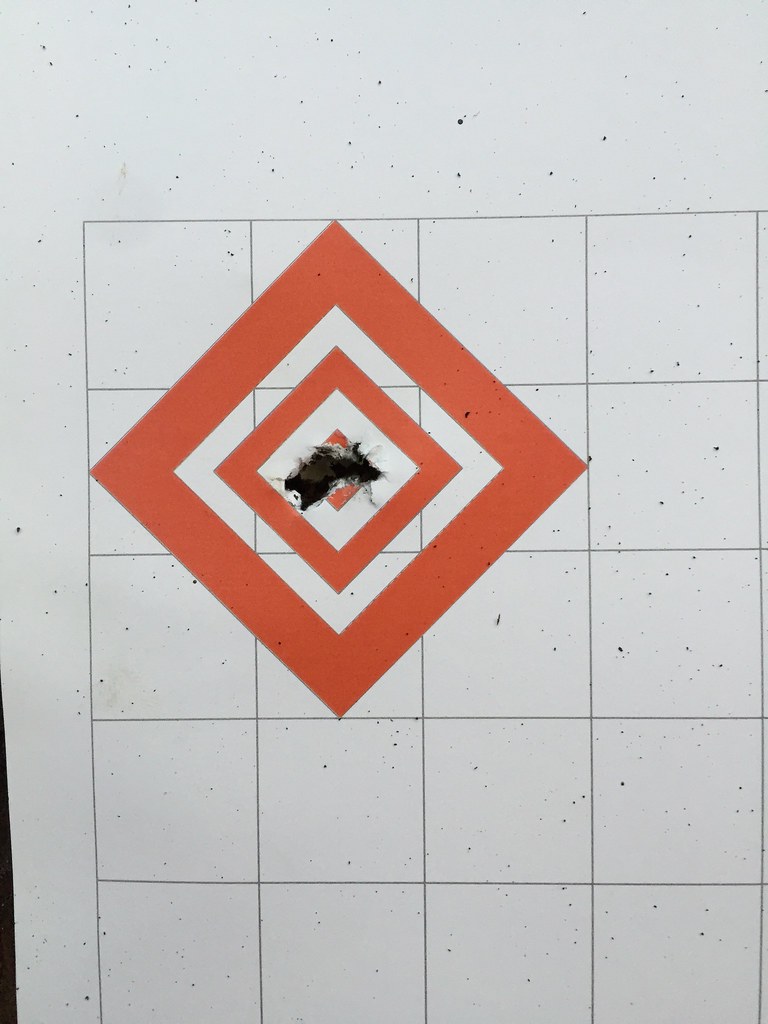

Untitled by Custom Rifle, on FlickrShots 5-10 through the barrel

Untitled by Custom Rifle, on Flickr

Untitled by Custom Rifle, on Flickr

Borden Woodie

in Precision Riflesmith's Showcase

Posted

They aren't anymore......